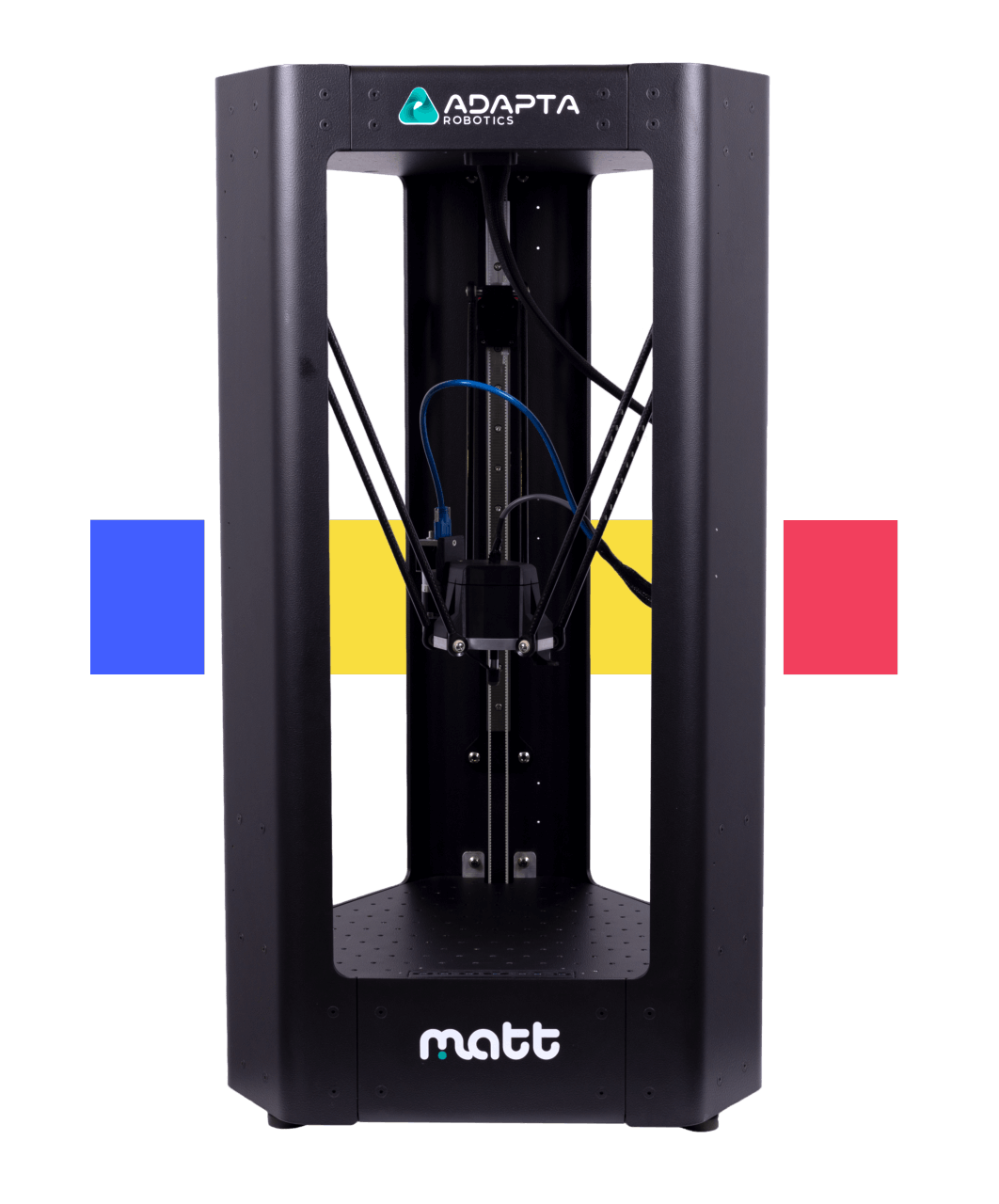

With a 1, 2 or 3-fingered custom end effector and add-ons that emulate any multi-touch gesture like tapping, pinching, swiping, and rotating, two high-resolution cameras, computer vision API, and alongside powerful electronics and robust engineering, the device testing robot easily replicates user interaction. MATT performs fully automated device test cycles for both hardware and software, relieving manual testers of repetitive tasks while providing consistent results and increasing productivity.

MATT comes equipped with a capacitive stylus effector that moves at blazing-fast speed. Replicate device-user interactions like screen tap, swipe, and zoom gestures for outstanding test accuracy.

Universal Input / Output and communication interfaces allow MATT to easily interact with external portable and built-in hardware devices and their components. Adjustable fixtures offer a versatile device mounting solution, from smartwatches and smartphones, to laptops, smart home appliances, IVI systems, and flight deck systems.

Advanced embedded software safely interacts with curved screens and all device shapes.

The effector features three capacitive stylus nibs which move independently to replicate natural tap, swipe, pinch and rotate user interactions with device touchscreens and buttons. MATT’s fingers are serviceable to ensure fitness for any material and capacitance requirements.

MATT is suitable for a wide range of testing scenarios. Efficient and simple test sequence setup procedures leverage automation to reduce human interaction and eliminate test calibration errors. Ready for integration with testing use cases across the entire product cycle, from R&D to end of line testing covering stress testing, performance testing, functional testing, response time testing & more.

Fully conceived, designed, and assembled in-house by our dedicated engineers and developers for adaptability of custom integration requirements, including size and features. Always made with the highest-quality components originating from the United States and the European Union that will never be subject to foreign direct product rule (FDPR) or other export controls due to national security concerns.

We help businesses develop smart, integrated solutions that combine sleek hardware and user interfaces with powerful software and connectivity capabilities.